.png)

Issue 7 March 2023

BBJ Max - 9 over the Cascades in Washington State

This issue catch Ms. Lauri Church and her amazing team at Comlux / Indiana - the leading US completion company for narrow-body VVIP

F E A T U R E S

1 Aerospace Technologies Group (ATG) - The Great Shade Show!

7 OmnAvia Interiors - Cabin Textiles & Oh So Much more!

11 Primadoona Lux - the Art of Pampering

18 Cabin Culture - The Inside Dope on VVIP travel

26 Jetzign Feature - Lauri Church and the Comlux Design Team

31 Boeing Business Jets - a 26 year retrospective

Issue 7 March 2023

JetCabin Freshbook 2023 . all rights reserved

f r e s h b o o k . a e r o

Publisher

Editor

Editorial

Advertising

Directory Listings

RWR Designs GP LLC - Texas U.S.A.

Rick W. Roseman

directorylistings@freshbook.aero

Freshbook Magazine is a division of JetCabin Freshbook (freshbook.aero), and is an all digital publication, distributed globally to subscribers only. The subscription rate for any / all legitimate individuals or companies directly involved in the interiors sector of business or commercial aviation, is: $0 (no cost).

Advertising rates are available via our media pack.

Visit our Advertising page here.

JetCabin Freshbook

3206 La Paz Lane

Santa Fe, NM 87507 (u.s.a.)

If you change jobs or otherwise will no longer have a valid subscription email, please notify:

circulation@freshbook.aero

D E P A R T M E N T S

Boeing 787-9 at sunset / photo courtesy of Boeing

Words from the Editor

In the northern hemisphere at least, Spring officially starts on March 20th. But for the sake of this little ditty (and myself), I'm moving it up to today, March 3rd. Why, because as publisher of this magazine, I can do such things and because I largely live in my own fantasy world anyway. I believe that a careful amalgamation of truth and fiction in one's daily headspace is good. There's a lot wrong with the world anyway so it's often good to reinvent the things you don't like. In this case, it's the length of winter so I'm shortening it by 17 days. Besides, I hate coats! There's too many pockets to get my keys lost in - and unless I'm skiing, frankly I find cold weather a little off-putting.

But there's a few other reasons I chose March 3rd. Firstly, Steve Fossett, on this day in 2005, became the first person to fly a plane solo, non-stop around the globe without refueling. Fossett made the first solo nonstop unrefueled fixed-wing aircraft flight around the world taking off on February 28 and landing back on March 3rd. He took off from Salina, Kansas, where he was assisted by faculty members and students from Kansas State University, and flew eastbound with the prevailing winds, returning to Salina 67 hours, 1 minute, and 10 seconds later, without refueling or making intermediate landings. His average speed of 342.2 mph (550.7 km/h) was also the absolute world record for "speed around the world, nonstop and non-refueled." His aircraft, the Virgin Atlantic Global Flyer, had a carbon fiber reinforced plastic airframe with a single Williams FJ44 turbofan engine. It was designed and built by Burt Rutan and his company, Scaled Composites, for long-distance solo flight. The fuel fraction, the weight of the fuel divided by the weight of the aircraft at take-off, was 83 percent.

Also on this day In history in 1845, Florida became the 27th state of the United States of America. A little later, on the same day in 1931 and after over a century, a little poem written by Francis Scott Key was finally established as the U.S. National Anthem. The lyrics of the song were written on September 14, 1814, while Key observed the British invasion of Fort Mc Henry, a war zone located in Maryland, USA. “The Star-Spangled Banner” composition was inspired by a flag that remained standing, even after several hundred bombings.

And again on March 3rd, in 1966 was a biggie! The BBC began broadcasting television programs in color. I'm quite sure that was a thrill for the Monarchy, given the fact that Blenheim Palace was exceedingly rainy and muddy that year, severely curtailing bird hunts and other such royal outings.

And bringing us completely current, March 3rd, 2023 will stand as the day our 7th issue of JetCabin Freshbook Magazine was published, quite coincidentally on the 1st day of Spring!

That's my story and I'm stickin' to it!

Richard Roseman - Co-founder / Editor

First Visit? JCF Magazine is about jet interiors, and only jet interiors; the designers that design them, the centers that build them and above all, the cabin supplier groups - worldwide, that ultimately make it all possible.

If your company belongs to one of these groups, let yourself subscribe to something worthwhile for a change. Stay fresh, participate and grow .

VISION

We’re Changing the Way you think about Aviation Magazines

No flip viewers...no thumbing pages, no zooming to read text or adjusting scale to see images. Just smooth scrollable content, smartly written feature articles, full-width ads from the top companies in the world. Plus exciting departments that bring the FRESHEST in new rollouts and present the latest trends. Plus you'll always find glimpses of the near-term future of cabin design and products. And best of all, it's all interactive with video, live links and instant access to the people and extended content you're interested in.

%20copy%207.png)

Article by: Rick Roseman

Window shades have literally been around since the very beginnings of commercial and private aviation. Remember the venerable Boeing 314 Clipper, the Flying Boat that to this day, still marks the golden age of air travel? Even in 1940 as Pan Am first flew their well-to-do customers from San Francisco to Honolulu, they weren’t about to mar their passengers’ posh travel experience by allowing the harsh sun to rake across them as they napped. And as beautiful as she was, the Clipper lumbered along at 155 mph making the trip an exhausting 19 hours. For that kind of money and that length of time in the air, Pan Am went out of their way to pamper their passengers and one such pampering was hand-sewn accordion style window shades. No, they weren’t electrically operated and yes, there was far too much light bleed to eclipse the low afternoon sun – but they sufficed, and so began the window shade’s enduring indispensable place among the passenger accoutrements of commercial air travel!

And in the sixties, not long after the B-707 entered service, Boeing introduced a more simplified plastic ‘blade’ that the passenger could simply raise or lower. They weren’t as fancy as the Clipper’s hand-sewn shade, but they were cheaper to manufacture and far easier to maintain.

Rather needless to say, in the years since, the ubiquitous aviation window shade has come a long way. And who better to talk with about that, than the global market leader in modern aircraft window shades, Aerospace Technologies Group (ATG), based in Boca Raton, FL.

I was lucky enough to sit down with Mr. Mario Ceste, ATG’s CEO for a frank conversation about where aviation window shades are, now some 80 years own from the Clipper’s maiden voyage and why their company appears to be the gold-standard. I conducted the interview Q&A style and we started - with where they started.

JCF: So, Mario, why don’t we start with how ATG got it’s start?

MC: ATG was founded in 1998 so this is our 25th year and we've been in Florida the whole time - originally in Boynton Beach and then eventually to the Florida Atlantic University Research Park here in 2011 located in Boca Raton. The university and research park actually reside on the old army training base from the 1920s. In fact, there's still an airport there and then the rest of the land was given to the university and years later the state carved out a section of the land to incorporate the research park. We're one of the few manufacturing companies that is actually located within the park

today.

JCF: And may I ask what your facility size is?”

MC: “Yes, so we presently have 100,000+ sq. ft.in two buildings

JCF: And is pretty much everything done out of that location?”

MC: Yes, everything, all our admin and executive staff, our engineering and new product development and all our manufacturing of course, all out of the one location. Now obviously we have some satellite locations within some of our larger OEMs [customers], small support presences necessary in providing on-site supports for our products during line integration.”

JCF: But fully all your manufacturing is done in house?

MC: Absolutely. Obviously some of our key vendors manufacture sub-components for us. But yes all primary manufacturing and certainly all assembly is done right here. I also should point out that we are also are a designated 145 repair station as well.

JCF: And can you give our readers an idea of your size in terms of employees?

MC: Sure, at present, we are sitting at just over 150 employees – and in the next 12 to 18 months based on our current growth, that number will climb to roughly 200.

JCF: Ok, so let's talk a little bit about your customer base. Can you share a little about how they are divided up?

MC: Well, our legacy – that is the roots of our company, was formed around business jets. We started out in that world as an OEM option. Our products back then were not at all an integrated part of their manufacturing line. Back in those days some OEMs didn't do any of the of the finishing of the interiors. They just built the green aircraft and then turned it over to completion centers and the MROs for final fit out. Today, when you buy a business jet the OEM completes the aircraft totally – full interior and all. In those early days, our electric shade was an option, just as it was with automobiles many years back. Since the business jet industry matured in that regard. Beginning around 2010, the business shifted and now, we became a standard line fit. With reliability we have achieved in our electric window shade nearly all new platforms being introduced include our electric shade as standard equipment. In fact we are a line fit for all bizjet OEM’s with the exception of just one.”

JCF: Ok, and I’m sure for most of our readers, the term line-fit is clear but for those who may not know, can you explain that a bit?

MC: Sure. So, when you say line fit it simply means that every aircraft, they build your standard equipment installed as a part of the aircraft. Just for instance, where every airplane comes with seats and sidewalls.

JCF: So, your window shades are an automatic install. Is that what line-fit refers to?”

MC: Yes, in most cases. But to perhaps put a finer point on it, line fit can actually have two meanings. 1) it means that when the aircraft is built at the OEM’s facility it's an option or a feature in the aircraft that the customer can elect for as the aircraft is being built – versus an aftermarket install where it would go to a secondary facility like an MRO for install. But most often it means a standard feature that comes with the aircraft. Not much different than an automobile.

We have refined our manufacturing processes so in the final stages of assembly we can add the custom color components

JCF: And so, does that mean your fully assembled window shades are kept as inventoried stock at the OEMs?

MC: Well will depend. In some cases where there is color palette uniformity, then yes, certainly that’s what occurs. But on large cabin format jets and even a great number of mid-size jets, those pretty much are ordered with highly custom interiors by the customer.

So in those cases, we have to wait until palette choices have been made – and then we build those shades to order. In other words, we will put the finishing touches to the window shade on an order-by-order basis before they ship to the OEM for install. While today we view our business as mainly build to stock, its not truly 100% that way. We have refined our manufacturing processes so in the final stages of assembly we can add the custom color components. Five years ago, our standard lead time was 8-12 weeks, but today if the OEM provides us long range forecasting, we can deliver a complete set of window shades in a custom color in two weeks. This is only possible because we have implemented a “just-in-time manufacturing philosophy using a single piece flow.”

JCF: Ok, but to come back to my original question, can you give us a breakdown in your market segments?”

MC: Oh sure. Roughly 50% of our business is Business Jets, then roughly 40% commercial and the remaining 10% or so is VVIP, these are larger Boeing, Airbus size aircraft which are used for head of state or high wealth individuals who have essentially a flying apartment.”

JCF: Ok, well I think that’s a good segue into you very latest product, the AirBlade. I know this is a very significant new rollout for ATG so let’s get into it and maybe I’ll kick that off with a question. Let’s say I'm a customer for a minute and I've had your shades in my airplanes before. why do I want or need the AirBlade in my new jet?”

MC: Ok, so number one, the Air blade is not a business jet product because of the nature of its construction. The AirBlade was built solely to go after the commercial marketplace and targeted at commercial aircraft carriers, the typical airline that the vast majority of flyers utilize. And the genesis of the idea was that the wide body airplane on long haul international flights was going to be displaced by a certain amount by the long-haul single aisle aircraft that are entering the market; planes like the A321 XLR or 737Max that are now going transatlantic. JetBlue began serving routes like London / New York, Boston to London, and this summer New York / Paris etc. The premise was that single aisle long range aircraft would open up point to point international travel from Hartford to Manchester (UK) as an example, and in that environment the traveler who would sit up front is likely to be a traveler who would sit in business class on the traditional wide body. The airline wants to create a business jet experience for the customer in that single aisle aircraft.”

JCF: Ok I’m not sure I understand the reason though. Is that because the single aircraft wouldn't be a three class aircraft? it would only be two classes?”

MC: Yes, that’s correct. Basically, business and economy, although these days as you know, economy is often divided up into a few sub-classes with different price points based on seat pitch, legroom etc. But for your long-haul business class, like say New York / London or Paris / Dubai, you will get a lay-flat mini-suite that had only been available on a widebody aircraft. Ironically the US carriers are slow to adopt the mini suite on single isle but the European and Middle East carriers are clearly leading the way. The major exception is JetBlue with its Mint Class and others are coming along like Air Lingus flying the A-321 Neo from Hartford to Dublin with a 2-1-2 configuration.”

BBJ Max Concept by: Cheryl Pelly Design

"The top DESIGN studios around the world are absolutely the ones that inform the industry and set the new trends."

Jetzign is where we highlight the very latest from the top designers and studios. Whether it be the iconic independents or the great design departments within the world's top completion centers, this is where you will find their latest works - and always with an emphasis on the near-term future of cabin design.

SkyYacht ONE / courtesy: Sotto Studios

%20copy.png)

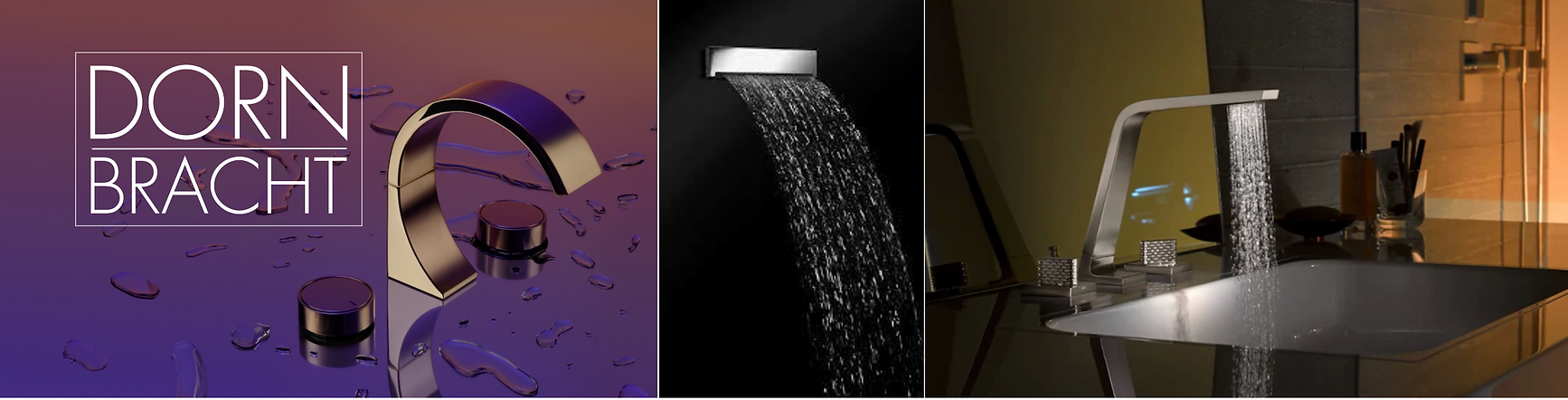

A World Of Textiles, Leathers & Interior Products . . . All Under One Roof

Interview & article by: Richard W. Roseman

Experience has taught me that when someone truly loves something from an early age and then makes it their life’s pursuit . . . they're generally very good at it. I have known Robin Butler for only a couple of years but in that time, the one thing I have learned about him is that he has (and always has had) a true love of textiles; everything from the weaves, the color, the textures, their tactile feel, and everything else that makes textiles special to people like . . . well, like Robin.

And his passion dates all the way back to early adulthood.

Mr. Butler studied Textile Technology at North Carolina State and his initial entry into the textile industry was selling textile machinery. “And from that job” he says “I learned pretty fast that I was not a process guy. I was a product guy. It’s the textures, the patterns, the feel [of the final product] that turned me on.”

In the wake of that resounding self-revelation, Butler knew it was time for a change.

“I went to work for a company called Langenthal which is now Lantal Textiles, in late 1984 and was moved to Seattle in ‘85 to manage their customer service office - taking care of Boeing, and at the time, McDonnell Douglas’ industrial and interior design groups - both OEM's. So, my immersion was in the commercial airline industry initially with fabrics and carpet and some leather but primarily textiles.”

It was a good move and sent him down a path that had him dealing with ‘product’ all day, every day, his sweet spot you might say. But even more importantly was really getting absorbed into the culture of large OEMs - getting to understand their needs, likes, dislikes and what all the criteria that went into their decisions. But in the formation of young careers of course, it’s all about moving around and honing one’s focus, so in 1988, he found himself back in North Carolina.

“I started an independent Rep business in 1990, Spectra Interior Products” says Butler, “selling the same types of products but representing several complementary, but noncompeting, textile companies. Included were firms that produced upholstery and curtain fabrics, a carpet mill, and a company that offered a line of hand tufted carpet murals. I also picked up leather tannery, a seat cushion producer, and a woven blanket weaver. It was a broad array of products - generally within the airline space - and most were products purchased by the same group at the airlines and handled from an engineering perspective by the same interior engineering group. It was much like my previous employer had offered but a style array that all worked very well together.”

But to fast-forward just a bit, suffice to say, it all led to the inevitable formation of OmnAvia Interiors, which as I first (and embarrassingly) learned in our interview, is pronounced Om Navy-ya, rather than my butchered version. The two Latin words respectively refer to ‘all’ and ‘flight’ (or aviation.). The handle indeed sums it up nicely. OmnAvia is, in Mr. Butler’s own words is, “a one stop shop” offering his customer base an encompassing array of interior products, all under one roof and at very competitive price points. And it also represents the culmination of three decades of prior, highly focused experience in aviation textiles, leathers, and related goods. As I hinted in the beginning, if you truly love something, you’re generally destined to succeed if you stick with it. And Butler is certainly a man who has allowed his passion to guide him.

A-321 Neo

TCS World Travel Adventures

.png)

At the 2022 NBAA/BACE one visitor was overheard saying Primadonna’s display looked like a ‘jewel box’. In my research for this article and in becoming familiar with their products, the jewel box reference kept popping in my head. Have you ever strolled down Fifth Ave in NY or the Avenue Montaigne in Paris – and marveled at the windows of couture shops and accessory boutiques? Indeed, they evoke the same. They beckon us to walk through the door and not leave until a few jewels are brought home for ourselves – magical accoutrements to bring joy and enrich our surroundings. Primadonna is a small, specialized boutique firm specializing in bespoke goods for private aircraft. Are they the only firm offering such amenities? Certainly not, but Primadonna Lux has inarguably risen to a level of sui generis and irresistibleness that customers around the world have begun to place on their essentials list.

By: Melissa Tokoriyama / special contributor

Today I had the pleasure of sitting down with Ms. Mindy Elizalde, the company’s Marketing Director, to find out how they crafted their ‘jewel box’ and the journey that’s brought them here.

She begins the story with Jennifer Garner, Primadonna’s original founder and a former designer at Bombardier. “She saw a niche for what we're doing,” says Mindy, “and it started off very small. Jennifer was our guiding force and even today, her influence can be felt. After 19 years and lots of growth, she decided it was time to retire and began the search for a suitable new owner. Everybody here understood how change can be good, “ Mindy explains, “but can it also be hard - and so it was a period of transition. That’s when Seth Newman, our current CEO came into the picture. Seth had shown interest in obtaining Primadonna for a few years – so the timing was right.”

“Can you tell us what it’s been like on the heels of that transition?”

“Well, Seth is very involved with the day-to-day activities, and he's made a lot of positive improvements. He supports product development, which of course is huge in any business like ours. Very quickly after purchasing the business, he invested in moving our headquarters and production to a larger facility. We’re thrilled to have a larger work room, more employees etc. And so, we’re growing and adding to our capabilities. I think we have approximately 50 people on our team currently.”

“Mindy, as a company overall, what would you say your strong suit is?”

“That’s easy.” She replies without hesitation. “It’s our talent. Over the years we have assembled a ton of talent under roof and honestly that’s why our products are so loved by our customers. The craftspeople in our work room exude talent and expertise. There's no shortcut for building a team like ours."

Even our salespeople and upper management – there is a lot of talent there as well, people with heavy production, design, and support experience. Many have worked directly with OEM’s or aviation related companies. And so, more than anything, our success stems from our people. No question.”

“You talked about product development being a focus for Mr. Newman. Can you tell us a little bit about how new products come to happen at Primadonna? I mean is it a situation where someone at the OEMs or the completion centers reach out and say, we are in need of a new sleep solution or what have you - or is it rather something that you guys conceive of internally and then try to sell them to your customers?”

“I think it comes both ways. A good example is our FlexFrame. It’s one of our newest products. I’m sure you’ve seen some of the inflatable solutions and we were seeking to provide an innovative design with simplicity in mind. It works in between the seats so they don’t have to be adjusted. It fits right in the middle and the custom mattress fits on top delivering a very comfortable bed in minutes. Most importantly, it’s a super easy setup for the flight attendants. We reached out to numerous private flight attendants during our early development of FlexFrame. We wanted to know what would make it easier for them and less disruptive for the customer. They resoundingly said they wanted something easier, quicker to set up and if possible, something that didn’t require them to bend over or stoop.

Tranquil, sumptuous sleep

at 51,000 feet above the earth.

And that’s exactly what FlexFrame delivers, a quick set up, all from the standing position and an exceedingly comfortable bed, sans any cumbersome inflating / deflating air system.”

“So, it’s a lot of research, reaching out to your customers and then I assume field testing?”

“That’s correct. We want whatever products we develop to not only meet the intended use but exceed our customer’s expectations and at the same time, give our flight crews the confidence that they’re not ever going to experience any snags – even over long repeated use.

“We also are reintroducing our Quick Ship Collection, which provides luxury linens without the wait, while maintaining our same luxurious quality.”

The Collection has been curated for the immediate need using our lux sateen sheets. It includes a white rectangular, quilt decorated with the banding in your choice of eight colors and tailored to fit the mattresses in your aircraft. “The idea that this can all be produced and delivered to our customer in 10 days is quite amazing and obviously appealing to them. Another thing I wanted to point out is ‘scale’. It is so important to desig and I'm sure you're aware of that. For private aviation I think we understand scale at a high level, and we've perfected it.”

Can you give us an idea about who you’re generally working with. I mean like, is it predominately designers or procurement people or…?

From Cockpit Crew to Cabin Crew. . . the Inside Dope on the Rich & Famous at 51,000 Ft.

4:40 am EDT – Portland, Maine / Flight Log: March 6th, 2015

It was coming up on 17 years I had flown for Mr. Frederick; 17 good years. He always treated me well and whenever he was the only passenger on board, he would often invite me to dinner with him wherever we happened to be. We would exchange mostly frivolous conversation, which he seemed to enjoy. He was an intense individual by nature and so I think he enjoyed my sense of humor as levity to the otherwise demanding life he led. Still I was careful to not “get loose” with him as I’m inclined to do on occasion with my mates. The boss is the boss…and in this kind of job, it’s never a good idea to let that hierarchy get out of balance.

Edwin Alton Frederick had made his money fairly early in life becoming a millionaire by the time he was 30. He was a coffee importer and routinely traveled back-and-forth to places like Colombia, Nicaragua and Costa Rica. His first jet had been a Lear 55 back in the early 90s but since that time he had progressively worked his way up through the echelons; first with the falcon 50 then a Gulfstream lV and, as of ten months ago, a new Gulfstream 650.

The boss had always looked at his aircraft as tools more than anything or at least that's what he projected but in the case of the 650 he was prouder of it than anything he had ever owned or aspired to. He had employed an outside designer and labored with both her and Gulfstream's design department to get the interior perfect. She was quite elegant but not over-the-top. He always said he wanted the cabin to feel like his living room at home and save the curved sidewalls, that’s pretty much the way her cabins look and feel. It is comfortable, inviting and he’s always anxious to bring his colleagues and friends aboard.

More than most men I know, the boss has a refined appreciation for things. I never felt like he took for granted anything he has, including his family, the multiple homes he owned or even the clothes he wore. He had grown up the son of a policeman in Boothbay, MN (up the coast from Portland) where he shared a small house with four siblings. As he often said “we didn’t have two nickels to rub together” referring to his upbringing.

He appreciated the life he had and the journey that got him there. He was an innately skilled businessman and could smell bullshit a mile down the tracks. But with people he liked, he was always gracious and humble.

Just out of college, he bought a small coffee store in Portland where he had spent his adolescent years. It eventually lead to opening two more and that eventually led to meeting the “new products director” for Whole Foods in 2000. Whole Foods had purchased a piece of land in Portland’s central business district and were planning to build their first store in the state of Maine. They were seeking to have a local independent coffee bar inside the store.

“Portland this is echo foxtrot two-niner… we're rolling.”

When the opportunity came along he decided to make a trip back to Costa Rica where he was born and had lived until he was 13. He made three trips to a small village called Monteverde, not far from where he'd grown up. Before it was done he had locked up a deal to supply coffee to 29 whole foods in the northern tier states. The boss was a personable soft-spoken man and it's clear to me that his original desire was not to make a fortune but to bring a new coffee experience to his customers and to see and feel the coffee beans in the soil from which they came.

At any rate, by the time he was 32, he sat on a US coffee importing empire that stretched from Vancouver to Atlanta. And while he was proud of his accomplishments, I never got the sense that his demeanor and overall persona was much different than it had been back when he started that first coffee store.

The boss had called me two afternoons earlier asking me to file a flight plan to Miami, where he would pick up his daughter, then on to Anguilla in the British Carribean. Altogether it would be roughly nine hours in the air.

His only daughter, Anja would turn 21 in two days and she loved the Carribean, having lived on multiple islands during summers between collage semesters. But her big love affair was with Anguilla. Only 16 miles long and 3 miles wide, it was the northerly most island in the Lesse Antilles, and it was the crown of the British controlled Carribean territories. She'd worked there for two summers at one of the major resorts and scorned anyone who dared contest her assertion that Anguilla had the best beaches in the world.

It was early March and the pre-dawn air temperature was 11°; not uncommon for Maine this time of year. The cabin was almost as cold as the outside air when my crew and I arrived. I rubbed my hands as I crawled into the cockpit to fire up the APU.

The boss hadn't arrived yet but he wanted to be in the air by 5:30 so I knew he would be driving through the gates of the FBO at any moment.

It wasn't hard to spot his car. It was a Range Rover unlike any you’d find in the showroom. And it’s color matched the G650 identically.

The design team at Gulfstream / Long Beach had presented several paint schemes, all of which the boss politely declined. In fact his delayed decisions over paint was holding up the delivery of the aircraft when one day he showed up and spilled a small sack of coffee out onto the conference table. He told the designers this was the color he wanted. Three days later the sample was complete; a stunning rich coffee brown with a slight infusion of pearl essence. After looking at it only a few minutes he signed the order and the plane finally went for paint.

The aircraft had an uncommonly appealing signature and she was particularly beautiful in the morning or evening light. She had no stripes or markings of any kind other than the ‘November’ registration on the tail. The boss was proud of his decision about the exterior and I often received comments from FBO ground personnel and other owners about her striking appeal.

Inside the aircraft there was a large candy bowl that had been hard mounted onto a long credenza on the aircraft’s right side in the main cabin. It was filled with a sweet licorice candy that to the eye, were roasted coffee beans in every detail. Guests mostly assumed it WAS coffee beans and rarely partook. To say the boss was proud from where his fortune originated, was an understatement. He was constantly giving bags of fresh roasted coffee beans to friends, that had been grown in this region or that. He appreciated anybody who loved their coffee and always wanted their opinion. But it was rare they ever had more to say than he himself. For him coffee was much more than a drink. It was a delicacy and a ritual to be taken seriously. But this wasn't going to be a 'coffee' trip, nor anything related to business. It was his daughter's 21st birthday. It was time to kick back and exchange coffee beans for distilled Agave.

Right on schedule the gate opened and in came the boss in the Rover. He was the ultimate light traveler; rarely showing up with anything more than a duffel and a coffee earn bearing his company’s name Jolt. As he came up the stairway I could see his breath in the frigid morning air.

"Morning Jack" he said with a smile. "Hope I didn't get you out of bed too early."

"Never been to Anguilla," I said "kinda looking forward to this one." Our flight attendant Mandy took his coat and we closed the door immediately in order to get the cabin warm.

My first officer Peter Boles keyed the radio. "Portland, this is Echo-Foxtrot two-niner. . . we're rolling.

“Echo foxtrot you're cleared for three one left.”

At 5:21 we were airborne and climbed out as the pink light of dawn crested the eastern horizon. We made a slow right turn to bring us onto our southerly heading. It provided a gorgeous view of Portland’s bay and the coastline stretching South.

The one thing that was so noticeably different about the 650 versus other aircraft the boss had owned was how incredibly quiet she was. Even in the main cabin the high-pitched whine of the engines were dampened, almost to the point of being soothing.

We leveled off at 46,000 and the stars were still well in view above us. Our ETA showed to be 0920 local and except for a few thunderstorms over the Yucatán peninsula, the weather showed good all the way down.

%20copy%206.png)

Article & Retrospective by: Richard Roseman

In the spring of 2000, I signed a customer on a new BBJ, one of the first, and certainly

my first. As an aviation interior designer in those days, it was the prize, pretty much the project we all wanted, be it designer OR center. The whole program was barely two-years old but even then, we all knew it was the beginning of something big in private aviation. It had the Boeing pedigree, it had the status, and it was the largest production business jet ever conceived. To frame my enthusiasm a bit, it was something akin to Jerry Buss's excitement when he bought the LA Lakers in 1976. But the really cool thing, and what I remember most, was that my client was as excited as I was. I remember sitting with him on our first post-contract meeting in London. Even though he was ten years my senior and way cooler, there was no hiding it. He was an eight-year-old boy on Christmas morning. . . and so was I. We both had our first BBJ and for Boeing's new division, it was the begining of a legacy even they could not have imagined.

JCF Magazine takes a look back on the history of BBJ. How it was formed, who its initial customers were and the program's unprecedented expansion. And lastly, how it's forever changed the notion of a business jet.

Sources: Boeing Business Jets™, Business INSIDER™, Jetstream™ and Wikapedia

An early shot of the venerable BBJ (737-700) on the ramp at sunset in southern California. This version, as with many others of the day included some of the first blended winglets by Boeing Aviation Partners - later absorbed by Boeing. The paint scheme was also typical on all BBJ demonstrator aircraft of the day.

To adequately understand how and why Boing Business Jets ever became a thing, you first need to know a little history about large commercial-size bizliners. It goes back much further than you might think - and in most cases, they took their beginnings from presidential aircraft, namely the first US presidents to travel by air - and a few other foreign heads of state around the world. But even before that, In 1930, Standard Oil of California, now known as Chevron, ordered a specially modified three-engine Model 80A, or Model 226, to fly its executives from city to city. The Model 80 was Boeing's first plane engineered for passenger operations. Then later, in 1959, President Eisenhower also began making official state flights in an executive configured Boeing. Specifically, he had three VC-137s, the Air Force derivative of the 707, and was the first to use the "Air Force One" call sign.

The US's first Air Force 1 - a Boeing 707 (VC-137B), utilized by Eisenhower, Kennedy, Johnson & Nixon

And then of course there was Howard Hugh's personal Boeing model 307 VIP aircraft - appropriately dubbed, the Flying Penthouse.

But let's not languish in the past too long. Suffice to say, extreme private wealth and foreign heads of state were living in the jet age and so it was inevitable they would eventually give up their fancy rail cars and smaller chartered aircraft for the larger, infinitely faster and more impressive transport category VIP configured aircraft. The big boys needed their toys . . . and they would have them. By the mid-nineties, the handwriting was on the wall - and who better to step up to the plate than the largest commercial aircraft OEM in the world. It was talked about. It was massaged and the demand, limited as it was, was clearly there.

And so it was. After nearly 70 years of converting airliners into business jets for companies, government departments, and private individuals, Boeing decided to create a series of large, customizable planes for the corporate market. And it would need to be a separate stand-alone division. In 1997 Boeing formally announced the new division, dubbing it Boeing Business Jets.

The first BBJ, based on the 737-700, rolled out on July 26, 1998 and had its first flight Sept. 4, 1998.

The first Boeing Business Jet concept was imagined in 1996 by Phil Condit, president of Boeing, and Jack Welch, chairman and CEO of General Electric as a joint venture project. Their first proposal was based on the Next-Generation 737-700 jet.

The plane could fly over 6,000 nautical miles nonstop, connecting cities like New York to Tokyo and London to Johannesburg, and offered more than ample cabin space in virtually any configuration desired by its owner - including bedrooms, divans, and offices.

By the end of 1998, the dedicated Boeing Business Jet assembly line was in full swing. The image to the right shows the very first BBJ owner being handed the keys by a Boeing executive. The only thing I have to compare that to, is my dad handing me the keys to the family Pontiac (reluctantly) so I could take my girlfriend to the Dairy Queen. We were unable to find the name of the lucky guy pictured above, so if anybody knows, let us know so we can call him up and ask him how long that high lasted.

But eventually, as eluded to in the beginning, I did finally get the the thrill of a new BBJ, just not as its owner. But we had a great client who really wanted to do something special and although the completion ran late (and for good reason), it was a stunning interior (pictured below) and with a very pleased customer.

ORBIT BBJ - delivered fall 2001 / RRAD Design

Left, in a shameless plug, is a photo of my own very first BBJ (hull number 006) for Swiss billionaire Thomas T. Bachmann (Zurich). Pictured is his private office in the aft potion of the main cabin. The completion was accomplished by the now defunct Ozark Aircraft Systems in Arkansas. The interior was highly custom consuming slightly over two years to complete.

The aircraft's accommodations included a large main salon, a lavish bedroom, bath and shower.

Richard Roseman Airborne Design©

According to Boeing, GE's Phil Condit was extremely passionate about the idea because he saw a promising market for customers who may want a bigger, more comfortable private jet that was then offered by the so called bizjet market; smaller aircraft like the Gulfstream or Bombardier business aircraft.

The plane took its first flight on September 4, 1998, captained by Mike Hewett and Mike Carriker. The 737 took off at 9:12 a.m. from Renton, Washington. The plane was used as a demonstrator aircraft and was certified by the Federal Aviation Administration and Europe's Joint Aviation Authorities on October 30, 1998.

But as time went on the orders piled up, often with years long backlogs. But as fast as the green aircraft were minted, they were sloted into completion centers both in the US and Europe. And they rolled out with increasingly more sophisticated interiors. Below is another example of an earlier BBJ (737-700 variant) by NY designer, Edese Doret.

In this example of another earlier BBJ 737-700 variant, NY designer Edese Doret created a beautiful retrofit for its new owner and the completion was realized by Aloft AeroArchitects in Deleware.

The monochromatic scheme presents the ideal airborne living room with sumptuous seating and dramatic ceiling & sidewall architecture.

Edese Doret Industrial Design©

Source: Robb Report

But in the same way that super-car owners eventually lost their excitement over the garden variety $350,000 options, so too did BBJ customers. For some, the regular BBJ was just a bit stubby. Not enough windows, not enough room and not quite enough cachet when they turned up in Nice for a beach holiday. And that ever-so-slight bit of discontent for BBJ's one lonely option, inevitably spawned a new idea. "Let's give 'em some bigger ones" said the powers to be - and so it was. Along came the variants. By the late 2000s, BBJ had announced the BBJ-2 (based on the 800 series) and eventually the BBJ-3 (based on the -900 platform). Later these longer versions of the 737 airframe were branded as the MAX series with three dash variants, -7, -8 and the -9.

And low and behold . . . there were plenty of takers!

See the full Press Release here.

Does your company have something our readers need to know about?

JCF Magazine celebrates the Global 7000 & 8000 this month, remarkable achievements by any measurement. Watch the video and note that on top of it all, you can breathe easier with Bombardier's Pũr Air and its advanced HEPA filter technology, arrive rested and refreshed with the Soleil circadian lighting system, experience the comfort of the industry’s lowest cabin altitude, and enjoy reduced lower back pressure with the Nuage seat and zero-gravity position.

.png)

%20copy.png)

%20copy.png)